Introducing the Formula M-MI 55-75 Rotary Screw Compressor from ABAC

Unleash Maximum Performance and Reliability

Compressed air plays a crucial role in many industries, ranging from powering manufacturing processes to running pneumatic tools. However, with energy costs being a significant expense, it's vital to have a high-performing, reliable, and energy-efficient compressor. The new range of Formula M Screw Compressors from ABAC solves this problem by embodying increased performance and reliability while reducing operating costs. The range is available in two configurations:

In this blog post, we take a closer look at the features that make Formula M a game-changer.

Key features

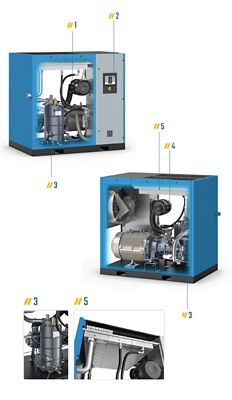

1. Introducing the latest screw elements technology

Formula M compressors use a new generation of screw elements that offer unparalleled performance, energy efficiency, and durability. With a new rotor profile that minimizes pressure losses, the compressors deliver higher flow rates with a lower power consumption. Furthermore, the screw elements are designed and manufactured in-house at ABAC's facilities in Belgium, ensuring meticulous craftsmanship and quality control throughout the production process.

2. Infographic controller

One of the standout features of Formula M air compressors is the state-of-the-art infographic controller. This controller allows operators to monitor and adjust the compressor's performance in real-time, adjust schedules for optimal energy consumption, and set up alerts for preventative maintenance. The infographic controller is also equipped with integrated connectivity, enabling energy optimization and facilitating cost savings through advanced monitoring and control capabilities.

3. Casted oil separator vessel

Formula M compressors feature a casted oil separator vessel with an integrated minimum pressure valve (MPV), which eliminates the risk of leakage and provides a reliable and secure operation. The MPV ensures a stable pressure level inside the vessel, maximizing oil separation efficiency, and extending the oil filter's lifespan.

4. Quality filtration

Formula M compressors come with a quality filtration system that safeguards internal components and prolongs the overall service life of the system. The filtration system comprises a pre-filter, oil filter, and air/oil separator, ensuring that only clean and dry compressed air is supplied to the end-users.

5. Separate coolers

Formula M rotary compressors come with separate oil and air coolers providing quality cooling and extended cooler lifespan. The separate coolers aid in temperature control, enhancing compressor efficiency and reliability. Moreover, the system incorporates gliding rails that enable effortless and secure removal for maintenance or servicing purposes.

ABAC Formula M-MI 55-75

ABAC Formula M-MI 55-75

ABAC Formula M-MI 55-75

ABAC Formula M-MI 55-75

- Filename

- ABAC-FormulaM-FormulaMI-web.pdf

- Size

- 694 KB

- Format

Key Differentiators

Key Differentiators

New Air End

The compression element is meticulously designed in-house, working in tandem with an IE4 efficiency motor. This synergistic combination delivers remarkable performance, reduces compression temperature, and ensures exceptional reliability. The result is an optimised system that operates efficiently while maintaining high levels of performance and dependability.

Thanks to its superior component design, the system is engineered to thrive in environments with high ambient temperatures, capable of operating reliably and efficiently in temperatures up to 46°C.

Fixed vs Variable

| FORMULA M – FIXED SPEED | FORMULA MI – VARIABLE SPEED |

|---|---|

| Built for long duty cycles and continuous operation | Ideal for highly efficient operation during fluctuating air demand |

| Gear Driven | Direct Driven - Permanent Magnet Motor (iPM) |

| ES4000Swipe with an intuitive user interface | Advanced ES4000T* touchscreen controller maximizes performance and efficiency |

| Superior technology compared to belt drive thanks to in-house air end design and gearbox | Energy savings of up to 35% compared to fixed-speed |

*ES4000Touch available as option for FS

iPM for Major Energy Savings

Energy takes up more than 70% of the cost of owning and operating a compressor. ABAC’s iPM technology was developed to give you significant energy savings. While traditional compressors only have one speed (100% on), iPM compressors adjust their motor speed to follow the fluctuating air demand that most production environments have.

As a result, the new Formula MI delivers energy savings of up to 35%. That means you can earn back the extra cost of the Formula MI 55-75kW (compared to a fixed-speed unit) in just 1 year.

How’s that for an easy decision?

ABAC Formula M-MI 55-75

ABAC Formula M-MI 55-75

ABAC Formula M-MI 55-75

ABAC Formula M-MI 55-75

- Filename

- ABAC-FormulaM-FormulaMI-web.pdf

- Size

- 694 KB

- Format

Popular Formula M-MI 55-75 Products

Formula M Screw Compressors from ABAC are the ultimate solution for high-performing and energy-efficient compressed air supply.

- With advanced connectivity, intuitive controls, quality filtration, and separate coolers, the compressors bring intelligence to your operations, reducing operating costs, and boosting productivity.

- The new generation of screw elements technology facilitates maximum performance, while the infographic controller helps optimize energy consumption.

- The casted oil separator vessel with an integrated minimum pressure valve and quality filtration system safeguard the internal components and prolong the compressor's lifespan.

In summary, with Formula M compressors, you have a reliable and efficient partner for all your compressed air needs, taking your operations to the next level.